Introduction of aluminum baffle ceiling

1, Brief description of aluminum baffle ceiling

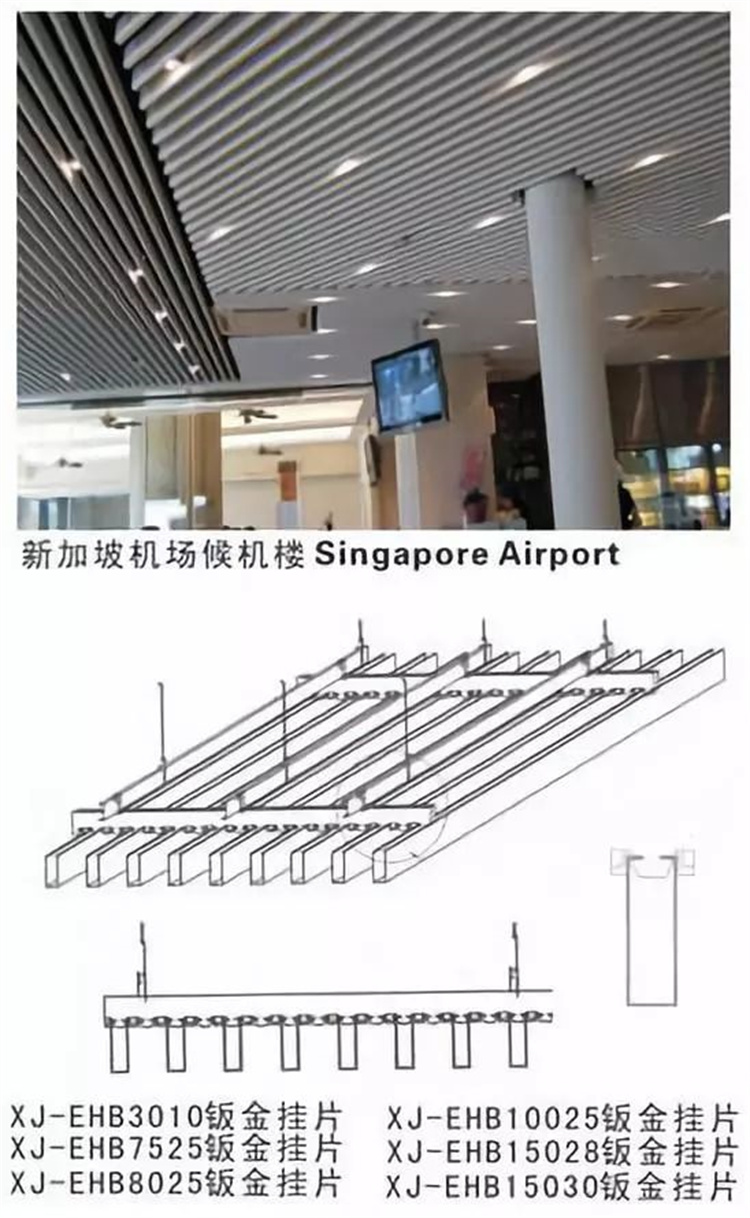

The size of the false ceiling panels is made of aluminum, with both perforated and smooth surfaces. The gaps between the ceiling strips are 15 mm wide and covered with original strips.

Surface treatment of the strips, aluminum ceiling strips, pre-painting, roller coating, or electrostatic spraying.

luminum baffle ceiling performance: sound insulation, removable, seam-sealing, fireproof, moisture-proof, anti-corrosion, can also leave gaps, beneficial for ventilation, has decorative effect, false ceiling panels can be used indoors and outdoors, is durable, and easy to clean.

2. Composition of false ceiling panels

System of ceiling tile manufacturers---a metal bar-shaped suspension system. The false ceiling panels

bars are stuck on the keels, and then suspended by steel rods, and the height is adjusted with nuts. The gaps between the ceiling strips have a standard clamping width, and the original strips cover the gaps. In addition, sound-absorbing materials can also provide sound insulation. The perimeter of the ceiling can be left blank or the corner of the wall can be used to close the edges with edge strips.

Materials of aluminum baffle ceiling- ceiling strips, keel profiles and edge profiles are made of aluminum alloy or hot-dip galvanized steel. The suspension rod is made of galvanized steel rod.

Production of aluminum baffle ceiling - using cold rolling technology, roll rolling or bending forming.

ceiling tile manufacturers surface treatment--roller painting or electrostatic spraying

Aluminum of ceiling tile manufacturers: surface degreasing, pickling, chromate treatment, two-layer coating and baked paint coating

Steel of ceiling systems: hot-dip galvanized, other materials such as aluminum

Ceiling tile manufacturers coating thickness (microns)

False ceiling panels surface: bottom layer 5 surface layer 2

False ceiling panels back: Bottom layer 5 Surface layer 2

3. Aluminum baffle ceiling appearance

Surface - ceiling strips, peripheral edge profiles

Smooth surface - no holes

Aluminum baffle ceiling perforated surface:

Standard holes: 2 mm in diameter, arranged at an oblique angle, occupying approximately 16% of the board area

Micropores: 1.8 mm in diameter, arranged at an oblique angle, accounting for approximately 22% of the board area (only for aluminum boards)

Color: ceiling strips, edge strips

Molding: hot-dip galvanized natural color or other colors customized as required

Keel: Hot-dip galvanized natural color or other colors customized as required

Glossiness: There are matt, mercerized, metallic, mirror paint and solarized mirror, etc.

4. False ceiling panels performance

Ceiling systems fire protection---aluminum and steel are non-combustible materials

Ceiling systems sound absorption performance ---- depends on the sound insulation material, the space above the ceiling and the drilling conditions

5. Aluminum baffle ceiling installation and maintenance

1). Installation procedure of ceiling systems: The ceiling technician will perform the construction, adjust each component, tighten the adjustable screw, install the keel, adjust its height, and clamp the ceiling strips to the keel profile.

2). Operation of ceiling systems: Use simple tools such as fine-toothed hacksaws

3).Ceiling systems maintenance: Clean with water, synthetic detergent or white oil. Soundproofing materials must not come into contact with liquids.

4) Maintenance of ceiling systems: Replaceable parts

5. Aluminum baffle ceiling application fields

Used in airports, subways, stations, business centers, hotels, restaurants, hospitals, offices, bedrooms, chefs, bathrooms, corridors