The development of the ceiling materials

The development of the ceiling materials:

the first generation ceiling materials are gypsum board, mineral wool board; the second generation ceiling is PVC; the third generation ceiling is metal ceiling.

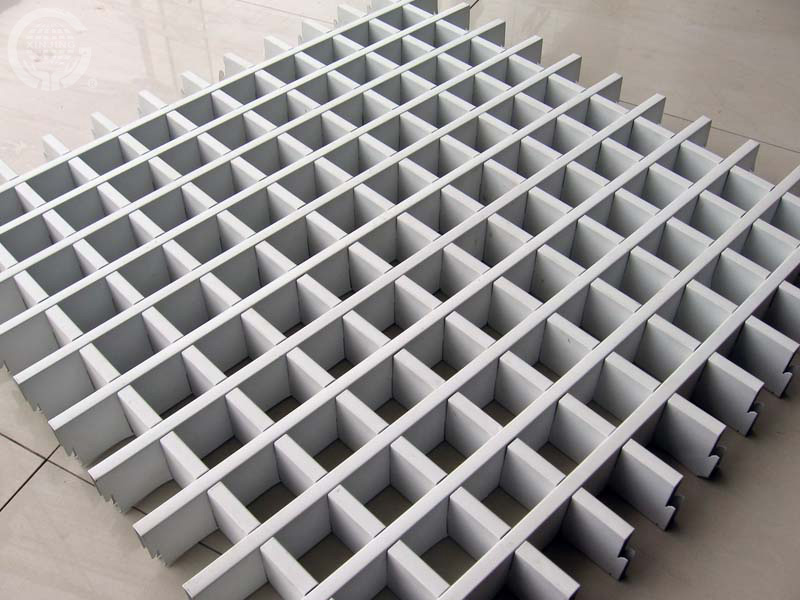

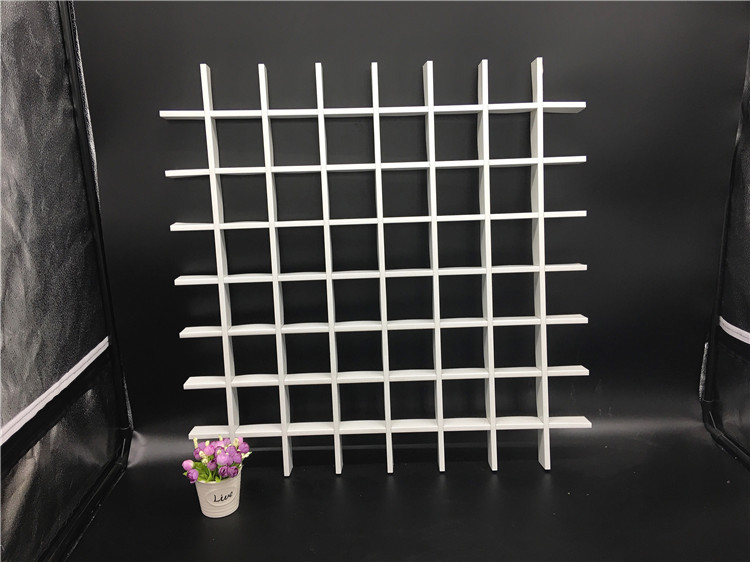

Ceiling types of aluminum ceiling materials:: aluminum veneer ceiling, aluminum honeycomb ceiling, standard square ceiling, hanging piece ceiling, C-shaped strip ceiling, U-shaped strip ceiling, D-shaped strip ceiling, aluminum strip ceiling, round tube Strip ceiling, square tube strip ceiling, perforated ceiling, etc.

Now ceiling materials of gypsum boards and mineral wool boards are also being continuously improved, including waterproof gypsum boards and sound-absorbing mineral wool boards. But the ceiling materials have a single plate shape and are not easy to scrub. The ceiling materials are installed on open frame keels and are mostly used in engineering. PVC ceiling materials have poor oxidation resistance,the ceiling types are not moisture-proof, not fire-proof, are easy to deform and change color, and PVC ceiling materials are mostly used in old-fashioned ordinary home improvement. With the improvement of people's requirements for decoration quality, now home decoration basically uses aluminum gussets to make ceiling materials.

The third generation ceiling materials are metal ceiling; 1. The smooth and flawless roll-coated plate is a kind of high-quality aluminum-magnesium alloy plate as the substrate, after strict degreasing and chemical treatment on the surface of the aluminum plate, roll-coating imported PVDF fluorocarbon coating, drying and curing, composite material. 2. The high-speed development of the roll-coated board is mainly due to the fact that it changes the traditional spray coating into continuous coating. After the roll-type coating is used, it is dried and solidified, which is different from the ordinary dip-coating chemical treatment method. It not only effectively controls the coating quality, but also eliminates defects such as dead edges and corners that are easy to occur in coating. At the same time, the ceiling materials can also be operated with unmarked treatment fluid to reduce environmental pollution and meet the environmental protection requirements of developed countries. 3. The color of the roller-coated ceiling is bright, which not only has the strength and excellent flexibility of the aluminum plate, but also has the good corrosion resistance and weather resistance of the paint film. The ceiling materials can not only withstand the deformation under high wind and strong pressure, but also can be cut, slitting, stamping, slotting, drilling, bending and compression molding at will, which can completely replace similar imported products. Therefore, Aluminum ceiling types are widely used in the construction industry: industrial plants, office buildings, shopping malls, stations, subways, airport buildings, modern large hangars, large stadiums, large clubs, etc. With the development of the times, the field of home decoration has also entered the mainstream of the decoration industry.