The production process for aluminum louver pergolas

The production process for aluminum louver pergolas typically involves several key steps, from material preparation to final assembly. Here's a detailed overview of how aluminum aluminium sun louvers are produced:

1,Material Selection and Preparation for aluminium sun louvers:

Aluminum is chosen for its durability, lightweight nature, and resistance to corrosion. High-quality aluminum extrusions are selected for the pergola components.

The aluminum material is inspected for defects and then prepared for the fabrication process.

2,Extrusion for aluminium sun louvers:

Aluminum profiles are formed through extrusion, where the aluminum billets are heated and forced through a die to create the desired shape.

This process forms the main structural components of the aluminum louvered awnings, including posts, beams, and louvers.

Quality control measures are implemented during extrusion to ensure the dimensions and surface finish meet specifications.

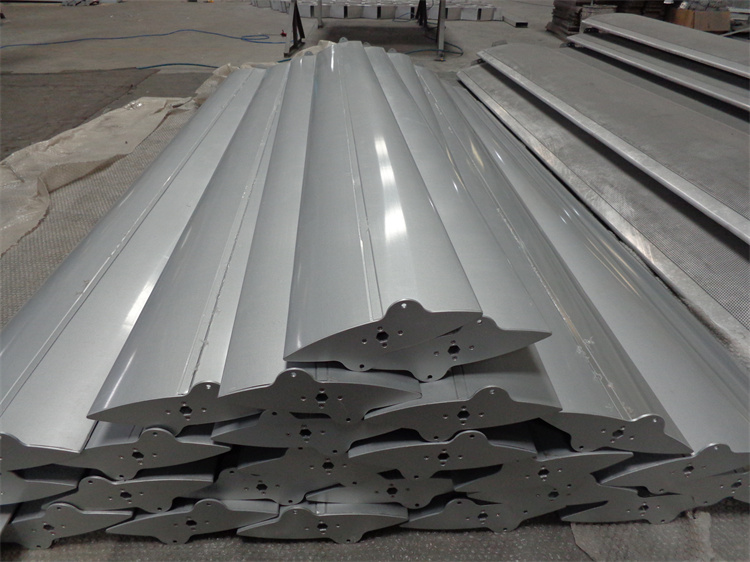

3,Cutting and Machining for aluminium sun louvers:

Once extruded, the aluminum profiles are cut to the required lengths using precision saws.

Machining processes such as drilling, tapping, and milling are performed to create holes for fasteners and other components.

4, Surface Treatment for aluminium sun louvers:

Aluminum surfaces are treated to enhance their appearance and durability.

Anodizing or powder coating processes are commonly used to provide protection against corrosion and to apply color finishes.

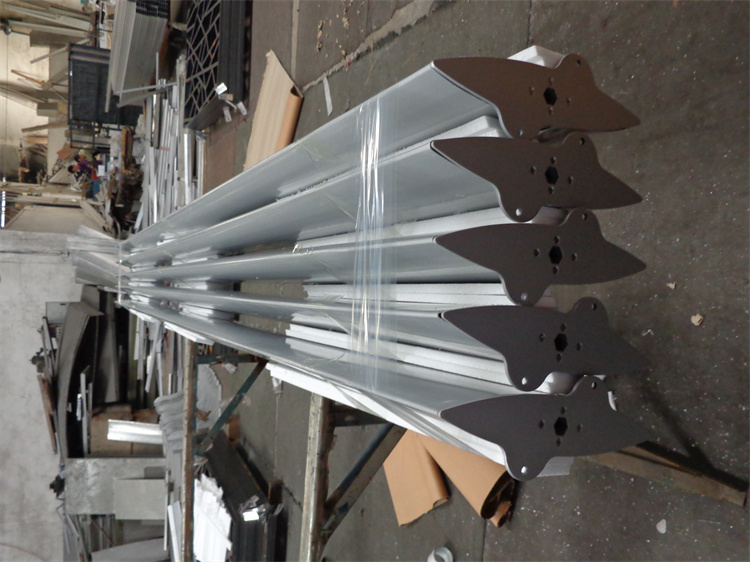

5,Assembly for aluminum exterior louvers:

The aluminum components are assembled according to the design specifications of aluminum louver pergolas .

Louvers are attached to the support beams using fasteners or specialized mounting hardware.

Additional components such as brackets, screws, and decorative elements are installed as needed.

6,Quality Assurance for aluminum louver pergolas:

Throughout the production process, rigorous quality checks are conducted to ensure that each component meets the required standards for dimensions, surface finish, and structural integrity.

Welded joints, if present, are inspected for strength and integrity.

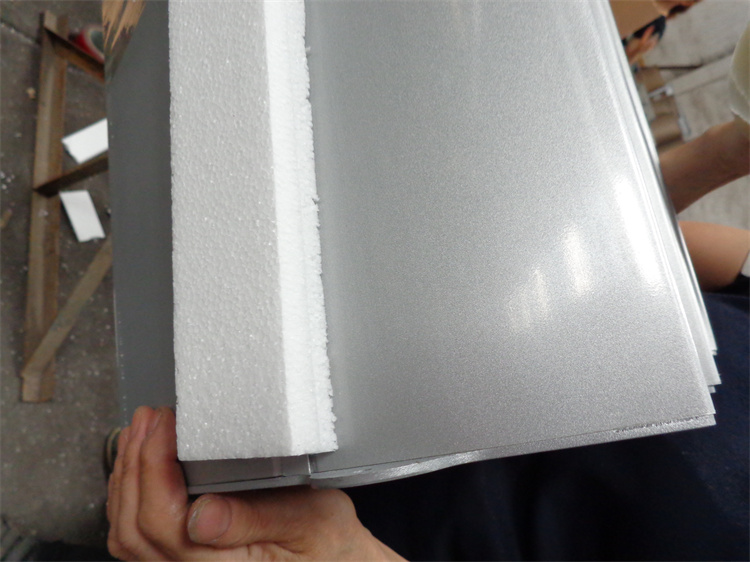

7, Packaging and Shipping for aluminum louver pergolas:

Once assembled and inspected, the aluminum louver pergolas are carefully packaged to protect them during transportation.

Packaging materials may include protective foam, cardboard, or other cushioning materials.

aluminum louvered awnings are shipped to distribution centers or directly to customers, depending on the manufacturer's distribution model.

8, Installation for aluminum louver pergolas :

Upon delivery, aluminum louver pergolas can be installed by the customer or by professional installers.

Detailed installation instructions of aluminum louver pergolas are typically provided, and some manufacturers may offer installation services as part of the purchase package.

By following these steps and maintaining strict quality control measures, aluminium sun louvers manufacturers can produce high-quality aluminum louver pergolas that are durable, aesthetically pleasing, and built to last.