What special requirements do perforated aluminum panels need to meet?

What special requirements do perforated aluminum panels need to meet? These will determine the pattern, spacing and materials of finished product manufacturing:

1. Perforated aluminum plates strength: Will the aluminum panels be used under pressure conditions? Strength depends on metal material, thickness and pattern. We can suggest the strongest combination for your application.

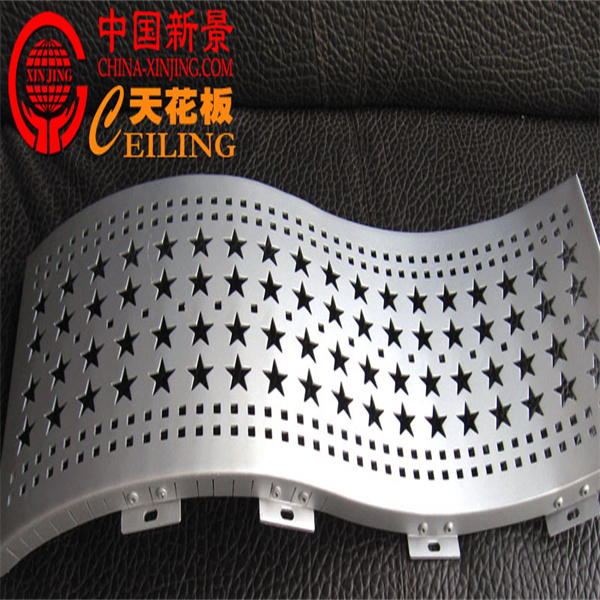

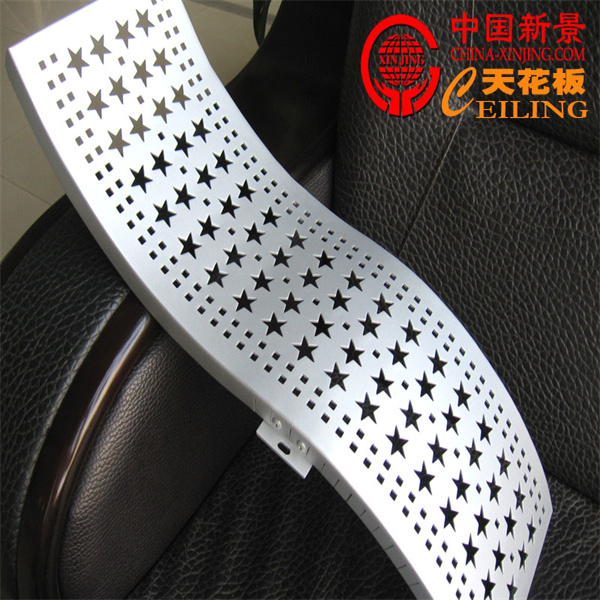

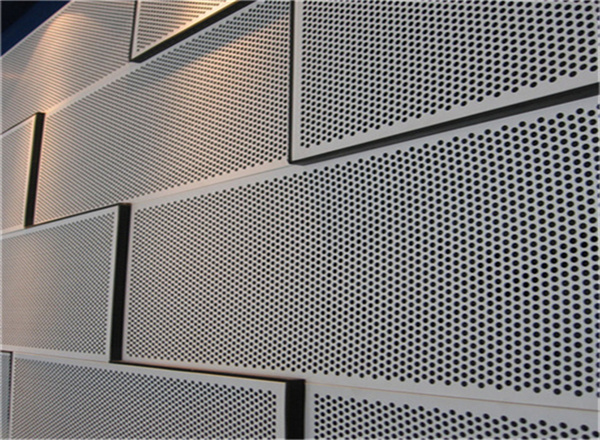

2. Perforated aluminum plates opening size, style and spacing: Different opening patterns will not only affect the strength of the panel, but also affect the expected work. The size, shape and distribution of holes all affect efficiency.

Perforated aluminum plates opening sizes: From the smallest round hole of 1.6mm to a 70mm hole, we can make any size to suit your project.

Perforated aluminum plates Opening Spacing: Standard spacing includes staggered, diagonal or straight, or we can custom create any arrangement to take full advantage of your bespoke design.

3. Professional processing technology for perforated aluminum plates: An extensive tool series and advanced stamping machines can be configured to provide thousands of different panel patterns, from standard shapes and sizes to unique custom decorations and architectural designs. Many popular shapes and sizes ready to go in stock, with additional build orders:

4. Shapes of perforated aluminum sheets: from round and rectangular to square, rounded square, slotted and hexagonal, the standard profile stock and custom perforated metal sheets range offers nearly 60 different combinations to suit most decorative and functional uses .